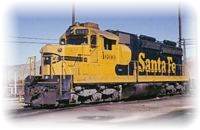

Click for full size

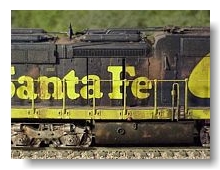

Right side overview. Athearn SD9 provided frame, trucks, cab, pilots, radiators. Atlas SD24 provided

core of long hood, dynamic blister, walkways and battery boxes. Tyco GP20 provided low

nose and cab front including number board housing. |

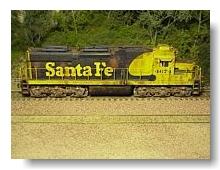

Click for full size

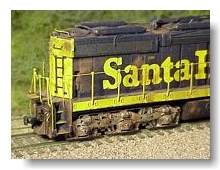

Right front. The inset nose step was cut out of the Tyco nose and backed by styrene. The odd-shaped nose

doors are modified Cannon parts. The blower bulge behind the cab was built up with styrene and body

putty. |

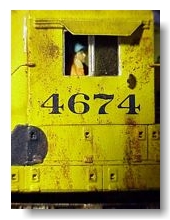

Click for full size

Right cab; looks like it's been a long hard day for the engineer. Weathering is done with chalks, stippled

into wet dull-cote with a very stiff flat-end brush. This method holds the chalk well while keeping its dry,

flakey texture intact. Varying colors, stippling pressure, chalk density, etc. result in a variety of effects. |

Click for full size

Right side center. The Atlas SD24 hood doors were sanded smooth, then .010" styrene overlays were cut to

fit, door openings cut in, then glued over the old doors. Cannon doors were installed, some in open

positions, others spliced to make odd-sized doors. |

Click for full size

Rear right side. Precision Scale plastic radiator fan housings were modified by flattening the central

domes. Dynamic fans are also Precision Scale but with domes left as-is. A Details West brake handle was

installed in a cutout of the hood side. |

Click for full size

Rear view. Details Associates ladder kits were installed. |